VDA 19.2 Technical Cleanliness in Assembly - Skilled Assistant Training

VDA QMC

BACKGROUND AND TOPICS

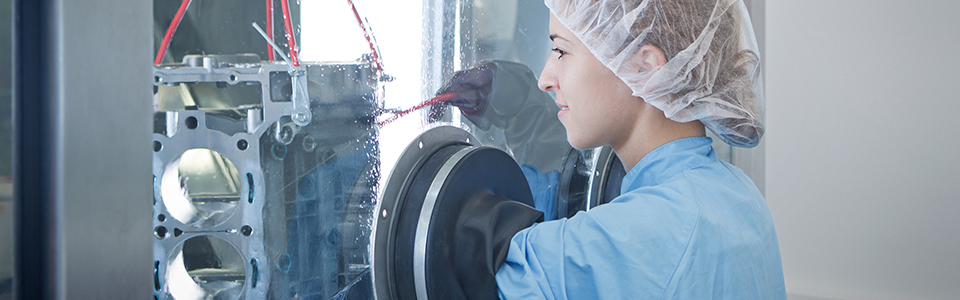

Technical Cleanliness of components and assembly groups is an important functional quality characteristic in the manufacture of modern vehicles.

Volume 19.1, “Inspection of Technical Cleanliness – Particulate Contamination of Functionally Relevant Automotive Components”, as the first comprehensive standard treatise, deals with the procedures for characterizing the state of cleanliness of products in the automotive quality chain. The red volume VDA 19.1 (formerly known as VDA 19) was first officially introduced by VDA in January 2005, and is available in a completely revised and extended edition since 2015.

Target Audience

This training aims to qualify automotive, supplier or service personnel who conduct cleanliness inspections. The imparted knowledge and insight into laboratory practice also constitute valuable tools for anyone confronted with the quality factor technical cleanliness in their daily work, such as construction, quality assurance, technical purchasing and sales personnel. Due to the similar cleanliness requirements in the sectors aerospace, hydraulics and precision engineering, this training is also suitable for personnel from these backgrounds.

Objectives

“VDA 19.1 Skilled Assistant” enables the participant to design and document cleanliness analyses according to VDA 19.1 and delivers insight into laboratory practice and the equipment and methods implemented there. Furthermore, the background to the technical necessity of cleanliness inspections and cleanly behavior is explained.

Concept and Methods

Theoretical principles

• Background on Technical Cleanliness in the automotive construction • Extraction procedures for detaching particles from components • Analytical procedures for the evaluation of particle contamination • Qualification of the cleanliness inspection via abatement measurements and blank value inspections • Documentation, cleanliness specification and examples of inspections Insight into laboratory practices After each theory lecture, an appropriate case study is presented to enable participants to practice and reinforce the knowledge gained. Video clips are also shown to explain the relevant laboratory tasks: • Selection of extraction methods according to the component concerned, followed by execution of the extraction procedure with start parameters • Selection of filtration und analysis methods as well as the procedure for a standard analysis • Evaluation and documentation of cleanliness analysesPrerequisites for Attendance

There are no prerequisites for attending this course.

Certificate of Qualification

After passing the written test you will receive a VDA qualification certificate for “VDA 19.1 Skilled Assistant”.